Material Handling Equipments

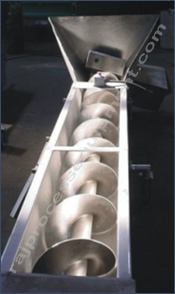

Screw conveyors in modern industry are often used horizontally or at a slight inclination as

an efficient way to move semi-solid materials. These can have a greater pitch spacing,

resulting in a higher capacity without an increase in rotation speed. They usually consist

of a trough containing either a spiral coiled around a shaft, driven at one end and held at

the other, or a Shaftless Spiral, driven at one end and free at the other.

Screw Conveyors can be operated with the flow of material inclined upward. When space

allows, this is a very economical method of elevating and conveying. It is important to

understand, however, that as the angle of inclination increases, the allowable capacity of a

given unit rapidly decreases.

RAJ Speciality in Screw Conveyor

- Designed to ensure smooth operation

- Jacketed designs to heat or cool the material during conveying

- Designs with hollow shafts for cooling or heating media

- Rugged screw flights to handle abrasive material with ease

- Various options for material of constructions depending upon product properties

- Designs with mechanical seals for operations under vacuum

- Cantilever screw designs

- Designed for easy operation and maintenance

- Easy removal of screw for cleaning

- GMP designs for food and pharmaceutical industry

Applications

- Fuels: chippings, straw, sawdust, wood dust, peat, pellets, carbon, etc.

- Waste matter: sludge, slaughter waste, manure, garbage, ash, bark, machine grindings, etc.

- Food products: grain, powder, sugar, salt, flour, rest products, etc.

- Various chemicals, minerals, dyes, pigments, starch, detergents etc.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing & Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management.

- Commissioning and Training.